5 Axis Mill Turn Centre

- 1 x MAZAK INTEGREX 200-IV-S. Twin spindle CNC turning/milling centre with ‘B’ axis. 36 station ATC capacity through main spindle, 65mm diameter. Full 5 axis simultaneous machining

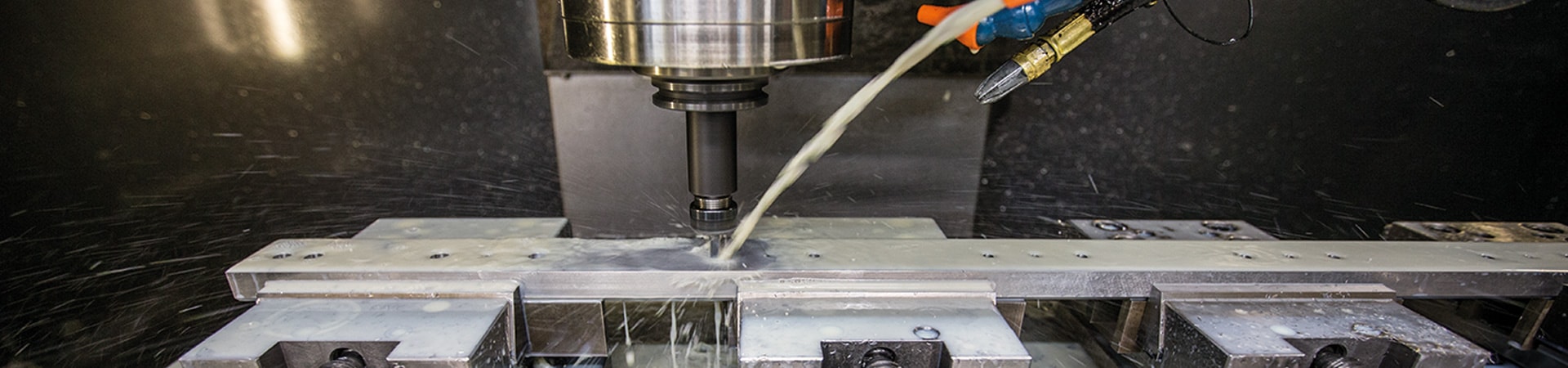

CNC High Speed Hard Metal Machining

- 1 x MIKRON HSM 400. High speed machining centre. 42,000rpm high precision spindle, 36 station tool changer, 7 station auto pallet changer, linear scales

CNC High Speed Graphite Machining

- 1 x MIKRON HSM 300 GRAPHITE MASTER. 54,000rpm High precision spindle, 35 station tool changer, 48 station auto pallet changer, linear scales

Shrink-fit tool holding

- 1 x Diebold ISG 3400 TWK. Self-contained bench-top model with integrated water cooling

CNC Turning Centre

- 1 x Hardinge GS51 CNC Lathe. Siemens 828D Controller. 12 station turret, capacity through spindle 51mm diameter, linear scales, high pressure coolant (30 bar)

- 1 x Hyundai HiT 18s CNC Lathe. Siemens HiTROL 840c colour control, 8 station turret, capacity though spindle 75mm diameter

- 1 x Mazak QT250MY CNC Lathe. Mazak Smooth Control, 12 station turret with 12 driven tools, 82mm capacity through spindle diameter, full C axis control and Y axis machining, high pressure coolant (15 bar)

CNC Spark & Wire Erosion Machining

- 1 x Agie Hyperspark 2. 90amp Generator, ‘C’ axis, 24 station auto electrode changing, programmable measuring cycles. Agie bril finishing of cavities (polish finish). Capacity 750 x 550 x 490mm

- 1 x Agie Hyperspark 2iQ. 72amp IPG high performance generator, ‘C’ axis, 28 station auto electrode changing, 4 axis path control, programmable measuring cycles. Agie bril finishing of cavities (polish finish).

- 2 x Sodick Die-Sink EDM, AG60L. 32 station tool changer with Erowa ITS ‘C’ axis and Erowa automatic chuck. Linear motor drive on all axis, LN2 control system, SGF nano-wear discharge unit, intelligent Q³VIC EDM, TMM3 high speed cutting of carbide materials. Capacity 950 x 740 x 450mm

- 1 x Sodick Wire Cut, SLC600G. Jumbo wire feeder, linear motor drive on X, Y, U % V axis, LN2W control system, High speed wire threading unit (SUPET JET AWT) & intelligent Q³VIC EDW 3D software. Capacity 800 x 570 x 340mm

- 1 x Sodick Wire Cut AG600L. Jumbo wire feeder, linear motor drive on X, Y, U % V axis, LN2W control system, High speed wire threading unit (SUPET JET AWT) & intelligent Q³VIC EDW 3D software. Capacity 800 x 570 x 340mm

- 1 x Sodick K1C Hi-Speed EDM Small Hole Drill

CNC Machining Centres

- 1 x Hurco VMX 42 DI. 15k Direct drive spindle, Rigid tapping, 2Gb RAM, 3D mould software, Ultipocket software, DXF software. Linear scales , high pressure through coolant (15 bar) Touch probe (Renishaw OMP2) Capacity 1070 x 610 x 710mm

- 1 x Hurco VM1. 20 station swing arm auto tool changer. Capacity 660 x 356 x 457mm

- 1 x Hurco VMX 30. Rigid tapping, 1gb RAM, 3D mould software, Ultipocket software, DXF software. Capacity 762 x 510 x 610mm

- 1 x Esiset ISO40 Taper Tool Pre-setting Machine

Lifting Equipment

- 1 x Overhead Gantry: 6300kgs capacity

- 5 x Overhead Gantry: 3,000kgs capacity

- 1 x Overhead Gantry: 5,000kgs capacity

- 1 x Sherpa Forklift: 500kgs capacity

- 1 x Hyster Forklift: Gas powered, 4,500kgs capacity

Cutting Equipment

- 1 x UE250A Horizontal Bandsaw

Milling & Drilling (Turret)

- 2 x XYZ Toolroom Model. Heidenhain metric/imperial 10-micron readout. Capacity 500 x 300 x 300mm

CNC Surface Grinding

- 1 x Andmar APS – 818S. Fully electric machine complete with coolant & 3 axis Accurate metric/imperial 1-micron resolution readout. Capacity 480 x 200mm

- 1 x Jones and Shipman 540X. Hydraulic machine complete with PG optidress ‘E’ wheel forming unit coolant & 2 axis Accurate III metric/imperial 1-micron resolution readout. Capacity 450 x 150mm

- 1 x Axe & Status KGS-510AHD. Horizontal spindle with programmable feeds on ‘Y’ & ‘Z’ axis. Capacity 1025 x 550 x 450mm

Surface & Form Grinding

- 2 x Jones and Shipman 540. Hydraulic machine complete with optidress, coolant & 2 axis Accurate III metric/imperial 1-micron resolution readout. Capacity 460 x 180 x 220mm

- 1 x Jones and Shipman 540L. Hydraulic machine complete with optidress, coolant & 2 axis Accurate III metric/imperial 1-micron resolution readout. Capacity 460 x 180 x 440mm

- 2 x Exe Toolroom Model. Complete with optical wheel dressing attachment & 2 axis Accurate III metric/imperial 1-micron resolution readout. Capacity 300 x 200 x 230mm

- 1 x Jones & Shipman 1400. Hydraulic machine complete with coolant & 2 axis Accurate III metric/imperial 1-micron resolution readout. Capacity 620 x 220 x 300mm

Cylindrical Grinding

- 1 x Jones and Shipman 1300 EIT. Internal/external machine complete with coolant, double swivel wheel head and radius dressing attachment. Sony 1 micron DRO. Capacity 265mm swing x 685mm between centres

- 1 x Jones and Shipman 1302 EIU. Universal hydraulic machine complete with coolant, double swivel wheel head and radius dressing attachment. Sony 1 micron DRO. Capacity 360mm swing x 685mm between centres

Turning

- 1 x Harrison M300 lathe. Complete with turnvision control, coolant, and 3 & 4 jaw chucks. Capacity 560mm diameter x 750mm between centres

- 1 x Harrison M350 lathe. Complete with turnvision control, taper turning attachment, coolant and 3 & 4 jaw chucks. Capacity 400mm diameter x 1,000mm between centres

Design Office

- 2 x Solid Works Office (current)

- 1 x Autodesk Powershape 2019

- 1 x Autodesk Powermill 2019, multi axis

- 1 x AutoCAD

- 1 x Makerbot Replicator & 3D printer

- 1 x Hewlett Packard Design Jet T730C colour plotter

- 1 x Hewlett Packard Design Jet A0-500C colour plotter

Inspection Equipment

- 1 x Full CNC CMM Global Classic 555

- 1 x Baty Venture Vision System

- 1 x Aberlink Xtreme CMM

- 1 x Prior Illuminated Stereomicroscope

- 3 x Granite Inspection Grade Surface Plates (600 x 600mm)

- 1 x Granite Inspection Grade Surface Plate (1000 x 1000mm)

- 1 x Granite Inspection Grade Surface Plate (800 x 500mm)

- 1 x Mitutoyo Vertical Heightmaster, 2 micron graduations 310 x 50mm

- 2 x Mitutoyo Linear Heightmaster 600, 1 micron graduations

- 1 x Mitutoyo Inspection Grade 115-piece metric Slip Gauges

- 2 x Mitutoyo Grade 2 115-piece metric Slip Gauges

- 1 x Johansson Grade 2 88-piece imperial Slip Gauges

- 1 x Set Mitutoyo Bore Gauges, 3-15mm

- 1 x Set Starrett Bore Gauges, 120-150mm

- 4 x Sylvac Hi-cal 300 Height Gauges

- 1 x Sylvac Z-cal 200 Height Gauges

Heat Treatment Plant

- 1 x Nabertherm N17/HR Hardening Furnace with C30 Controller

- 1 x Nabertherm N30/65HA Tempering Furnace

Laser Marking

- 1 x Gravograph LS100EXF Fibre Laser Marker (660 x 300 x 180mm)

Other Toolroom Equipment

- 2 x Horizontal Milling Attachment to suit Toolroom Bridgeports

- 1 x Rotary Table to suit Milling Machines

- 5 x Grindall Cylindrical Grinding Attachment

- 1 x Ronspin Cylindrical Grinding Attachment

- 2 x Magnetic SINE Chucks

- 3 x Non-magnetic SINE Plates

- 1 x NSK Sheenus Set Ultrasonic Polisher

- 1 x Atkin Mould Tool Water Pressure Flow & Filter Unit capable of testing water circuits to 10 bar pressure with a flow rate up to 25lts p/min

- 1 x Finnsonic M40i Industrial Ultrasonic Cleaner

- 1 x Finnsonic M40i Static Rinse Tank

Mould Trialing Cell

- 1 x Haitian ZEIII.2300.830 Electric With Built In Hydraulics- ZERES (Hybrid)

- 1 x Haitian ZEIII.900.210 Electric With Built In Hydraulics- ZERES (Hybrid)

- 1 x EPI Series Industrial Water Chiller